Electro-Slag Remelting Method of HSS Production

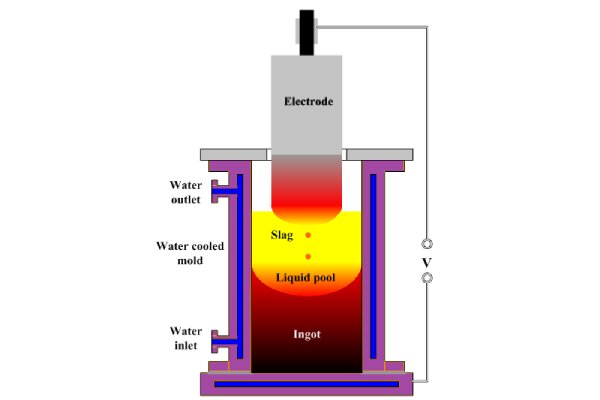

Electroslag Remelting (ESR) is a process of remelting a consumable electrode utilizing the heat generated by an electric current passing through a molten slag between the electrode and the solidifying ingot.

Advantages of Electroslag Remelting

- Deep desulfurization.

- Refining non-metallic inclusions.

- Homogeneous Distribution of non-metallic inclusions

- Fine Grain structure.

- No Shrinkage defects.

- Low macro-segregation.

- Good surface quality.

- Controllable process.

- We have an in-house facility for production of HSS through ESR method.

- We produce round bars starting from 65mm diameter up-to 400mm diameter in grades HSS M2 and HSS M35.

WhatsApp us

WhatsApp us